Key points of stainless steel antenna production

The application scenarios of daily physical stainless steel antennas refer to the physical antennas that we can see and directly contact, which are usually designed to receive or transmit specific types of wireless signals. The following are some common application scenarios of physical antennas:

TV antenna: Indoor and outdoor TV antennas are used to receive terrestrial digital TV (DTT) signals or satellite TV signals for watching TV programs.

Car antenna: Common antennas in cars include AM/FM radio antennas and car phone antennas (used for car phone systems and GPS navigation) to ensure the normal operation of communication and entertainment systems inside the car.

Satellite antenna: The satellite antenna installed on the roof of the house or on the vehicle is used to receive satellite TV signals or satellite Internet signals and provide high-speed broadband Internet and multi-channel TV services.

The order process for stainless steel antennas is as follows:

Details of communication with clients:

Determine the specific requirements of the customer, including the number of antenna sections, pipe diameter, head and tail accessories, extension length, collapsed length, etc.

Produce drawings:

Based on customer requirements and communication results, the design engineer begins to produce detailed engineering drawings.

The drawings should include all necessary dimensions, material specifications, processing techniques, and other information to ensure that the final product meets the customer's requirements and standards.

Sample making:

Once the drawings are completed, proceed with sample production.

Produce antenna samples using the selected stainless steel material and process for customer review and testing.

Samples need to meet the customer's design requirements and performance expectations, usually requiring strict quality control and testing. We will send the sample testing form and sample together to the customer.

Customer places an order:

After reviewing the samples, if the customer is satisfied, they will place an order.

After the order is confirmed, the formal production and manufacturing process begins.

These steps are typically a standard production process that ensures both customers and manufacturers have a clear understanding and recognition of the design and performance of the final product before starting mass production.

The production process of stainless steel antenna is described in detail as follows:

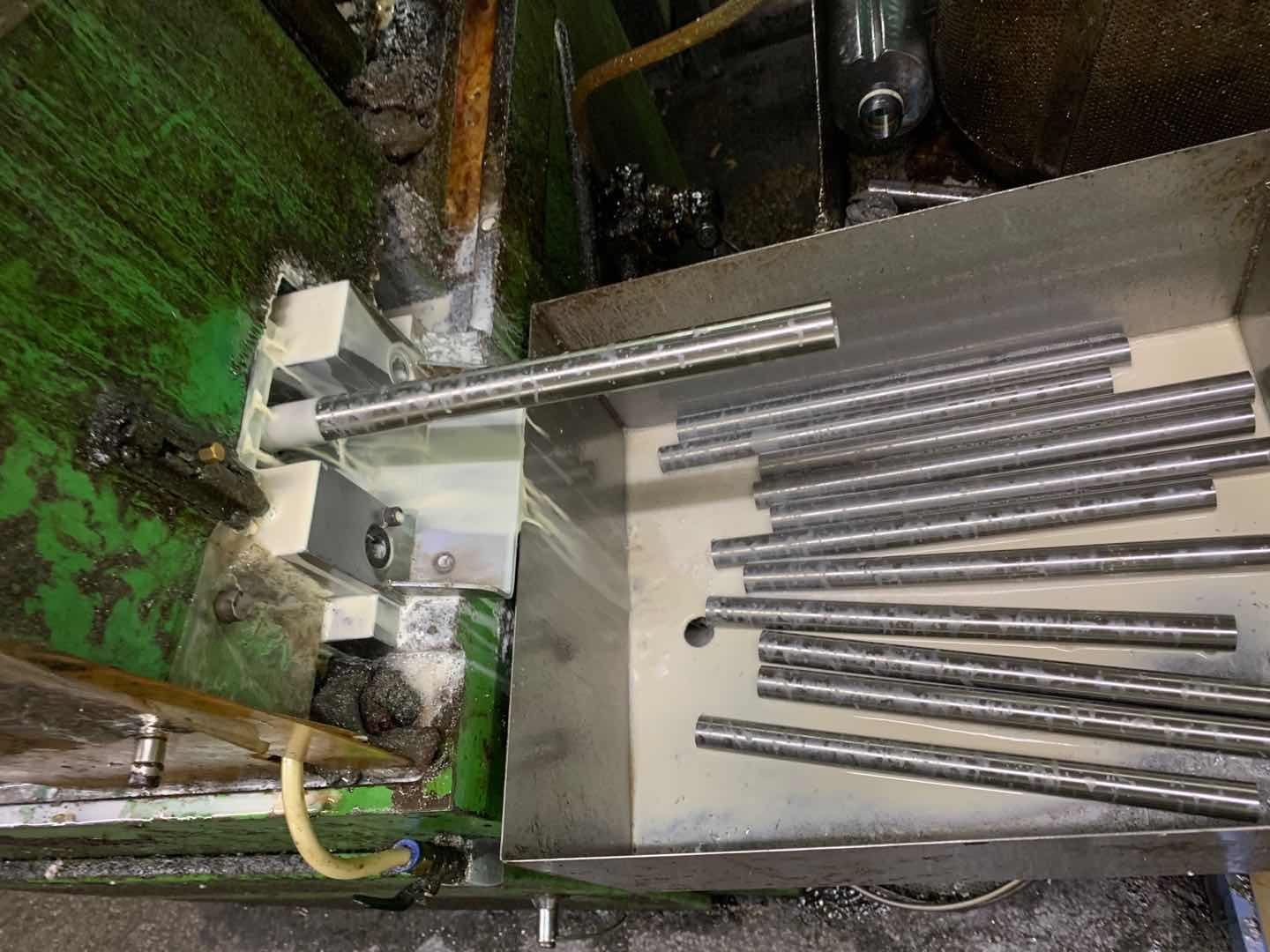

Cutting:

Use cutting equipment to cut stainless steel pipes into the required shape and size parts according to the design drawings and specifications.

Ensure cutting accuracy and surface quality to meet the needs of subsequent processing and assembly.

Assemble:

Dimple and groove are used for assembly on stainless steel pipes.

Inspection:

After assembly, conduct a comprehensive inspection and testing of the stainless steel antenna.

The inspection items include but are not limited to: visual inspection, dimensional measurement, durability testing, etc.

Ensure that the product meets the customer's technical requirements and quality standards.

Packing:

After completing the inspection, package the qualified stainless steel antenna.

Packaging usually adopts measures such as shock resistance, moisture resistance, and scratch resistance to ensure that products are not damaged during transportation and storage.

These steps constitute the production process of stainless steel antennas from raw materials to final products, and each step is crucial, affecting product quality and customer satisfaction.

Notes on Stainless Steel Antennas:

Top ball:

The size of the top ball of the antenna is usually determined by design requirements and can be a standard size or customized according to customer requirements.

The shape is generally spherical, but other shapes can also be customized according to the design.

The material is usually stainless steel or copper, and the specific choice depends on design requirements and environmental conditions (such as rust prevention requirements).

Base:

The material of the antenna base is usually stainless steel or copper to ensure that it is not easily damaged during long-term use.

LOGO:

Whether a logo is required on the maximum tube of the antenna depends on brand or customer requirements. If necessary, it is usually confirmed and implemented during the design phase.

Packing:

It is recommended to use pallets for packaging, which can effectively protect the antenna, especially the small balls at the top that are not easily broken. Pallet packaging can reduce the risk of damage during transportation.

Time:

It usually takes 10-12 days to complete sample production and confirmation.

The production time for bulk goods usually depends on the order quantity, which is usually 40-45 days.

If you are interested in our antenna, please feel free to contact us.

We are more than happy to provide a quotes and samples.

Work with professional factory, save time and effort, even save money!